How Vitamin B6 Pellet Coating Technology is Changing Formulation?

Let’s talk about the elephant in the R&D lab. You can spend years synthesizing the most biologically active, highly purified molecule known to modern science. You can back it up with double-blind, placebo-controlled clinical trials. But if your final dosage form tastes like a rusted battery, your patient compliance will flatline.

In the world of nutraceuticals and pharmaceuticals, taste is the ultimate gatekeeper of efficacy. And when it comes to notorious taste-profile offenders, Pyridoxine Hydrochloride (Vitamin B6) is public enemy number one.

Anyone who has ever tasted raw Pyridoxine knows the immediate, visceral reaction it provokes. It is aggressively bitter, leaving a lingering, metallic finish that seems impossible to wash away. For formulators designing chewable tablets, orally disintegrating tablets (ODTs), or pediatric suspensions, this presents a massive hurdle. You can’t just dump sugar on it and hope for the best.

Today, we are moving past archaic flavoring agents. We are looking at the micro-level physics of particle engineering. Specifically, we are going to dive deep into Vitamin B6 pellet coating technology. This isn’t just about making a vitamin palatable; it’s about utilizing advanced physical chemistry to protect the active pharmaceutical ingredient (API), control its release, and guarantee that the patient actually wants to take their medicine.

In this blog, we will explore the science of Vitamin B6 pellet coating technology, why traditional taste-masking fails, and how WBCIL is leading the charge in advanced delivery systems.

The Chemical Reality of Pyridoxine Hydrochloride

To understand the cure, you have to understand the disease. Why is Vitamin B6 so profoundly bitter?

Pyridoxine Hydrochloride is a water-soluble vitamin that plays a vital role in amino acid metabolism, neurotransmitter synthesis, and histamine management. Chemically, it is a pyridine derivative. Like many alkaloids and amine-containing compounds, its molecular structure fits perfectly into the TAS2R (Type 2 taste) receptors on the human tongue. These receptors evolved specifically to detect potentially toxic alkaloids in nature, triggering a hardwired gag reflex.

When a patient consumes an unmasked Pyridoxine formulation, the highly soluble vitamin immediately dissolves in the saliva. It floods the taste buds. The result is a sharp, acrid bitterness followed by a prolonged metallic footprint.

Historically, formulators tried to overwhelm these receptors with high-intensity sweeteners like sucralose, aspartame, or massive amounts of fructose. But today’s educated consumer demands clean labels. They want diabetic-friendly, keto-friendly, and pediatric-safe products. Therefore, finding methods for taste masking bitter APIs without sugar has become the holy grail of formulation science.

The most effective method? Don’t let the API touch the tongue at all. This is the fundamental premise of Vitamin B6 pellet coating technology.

Key Takeaways

- Advanced Vitamin B6 pellet coating technology utilizes a microscopic physical barrier. It revents Pyridoxine from interacting with taste receptors in the mouth.

- Solid-state liposomal pellets offer massive advantages over traditional liquid liposomes, solving critical issues like hydrolytic degradation, phase separation, and inaccurate dosing.

- Beyond taste-masking, liposomal technology protects the API from gastric acid degradation and, when combined with liposomes, actively boosts the bioavailability of Vitamin B6.

The Chemical Reality of Pyridoxine Hydrochloride

To understand the cure, you have to understand the disease. Why is Vitamin B6 so profoundly bitter?

Pyridoxine Hydrochloride is a water-soluble vitamin that plays a vital role in amino acid metabolism, neurotransmitter synthesis, and histamine management. Chemically, it is a pyridine derivative. Like many alkaloids and amine-containing compounds, its molecular structure fits perfectly into the TAS2R (Type 2 taste) receptors on the human tongue. These receptors evolved specifically to detect potentially toxic alkaloids in nature, triggering a hardwired gag reflex.

When a patient consumes an unmasked Pyridoxine formulation, the highly soluble vitamin immediately dissolves in the saliva. It floods the taste buds. The result is a sharp, acrid bitterness followed by a prolonged metallic footprint.

Historically, formulators tried to overwhelm these receptors with high-intensity sweeteners like sucralose, aspartame, or massive amounts of fructose. But today’s educated consumer demands clean labels. They want diabetic-friendly, keto-friendly, and pediatric-safe products. Therefore, finding methods for taste masking bitter APIs without sugar has become the holy grail of formulation science.

The most effective method? Don’t let the API touch the tongue at all. This is the fundamental premise of Vitamin B6 pellet coating technology.

The Mechanics of Vitamin B6 Pellet Coating Technology

So, what exactly is Vitamin B6 pellet coating technology? At its core, it is the process of applying a microscopic, uniform polymeric or lipid-based film over a spherical core of the active vitamin.

Think of it as putting the vitamin in a microscopic biological safe.

The process typically involves a fluid bed processor utilizing a bottom-spray (Wurster) technique.

- Core Generation: First, Pyridoxine Hydrochloride is either extruded and spheronized into small pellets, or layered onto neutral non-pareil seeds (like microcrystalline cellulose spheres).

- Fluidization: These cores are suspended in a column of precisely heated, high-velocity air.

- Coating Application: A specialized coating solution is atomized and sprayed from the bottom of the chamber. As the droplets hit the suspended pellets, the solvent rapidly evaporates, leaving behind a dense, continuous film.

The brilliance of Vitamin B6 pellet coating technology lies in its physical barrier. Because the polymer or lipid coating is insoluble in the neutral pH of human saliva (pH 6.5 – 7.4), the pellet passes through the mouth without releasing a single molecule of Pyridoxine.

If you have been wondering how to hide the bitter taste of Vitamin B6 completely, this is your scientific answer. The tongue cannot taste what it cannot physically touch. Furthermore, this physical barrier is the key to overcoming metallic aftertaste in Vitamin B6 formulations, effectively neutralizing the lingering unpleasantness that causes so many patients to abandon their supplement regimens.

Polymers vs. Liposomes: The Evolution of Coating

Not all coatings are created equal. When discussing Vitamin B6 pellet coating technology, we have to distinguish between older methods and cutting-edge innovations. Formulators often ask about the difference between polymer coating and liposomal encapsulation.

- Polymer Coating: Traditional pellet coating relies on polymers like ethylcellulose, HPMC (Hydroxypropyl methylcellulose), or methacrylic acid copolymers. These create a hard, physical shell. They are excellent at taste-masking and can be engineered for delayed release (e.g., enteric coatings that only dissolve in the intestines). However, they don’t actively do anything to help the body absorb the vitamin once the shell dissolves.

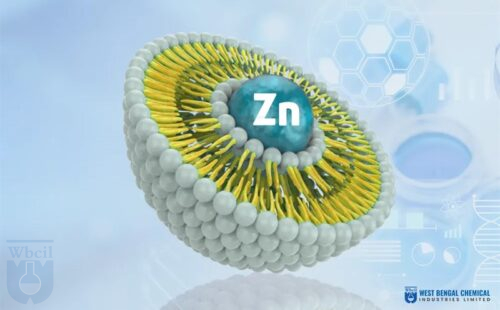

- Liposomal Encapsulation: Liposomes are spherical vesicles made of a phospholipid bilayer—the exact same material that makes up human cell membranes. When an API is encapsulated in a liposome, it acts like a biological Trojan Horse. The body recognizes the lipid bilayer as “friendly” material, allowing the vesicle to fuse directly with intestinal cell walls.

At WBCIL, our R&D team asked a pivotal question: What if we combined the physical stability of pellet technology with the enhanced absorption of liposomes?

This led to the development of liposomal pellets. We take liposomally encapsulated Vitamin B6 and process it into a dry, coated pellet form. This is a massive leap forward in Vitamin B6 pellet coating technology.

The Superiority of the Solid State: Why Pellets Beat Liquids?

Liposomal vitamins have been a buzzword for years, primarily sold as liquid suspensions. But any experienced formulator will tell you that liquid liposomes are a nightmare. They are highly susceptible to oxidation, require refrigeration, have short shelf-lives, and often suffer from lipid separation (phase inversion) over time.

By utilizing Vitamin B6 pellet coating technology to create solid-state liposomal pellets, we completely bypass these issues.

Let’s look at the advantages of liposomal pellets over liquid liposomes:

- Absolute Stability: Solid pellets do not suffer from the hydrolytic degradation that plagues aqueous liposomes.

- Precision Dosing: Liquids require the user to measure with a dropper—a notoriously inaccurate method. Pellets can be precisely dosed into capsules or sachets.

- Organoleptic Perfection: Even liquid liposomes can leak API into the suspension, causing bad taste. Coated pellets offer 100% taste isolation.

- Manufacturing Flexibility: The stability of liposomal pellets in capsule dosage forms is unparalleled. You can blend these pellets with other coated minerals or vitamins in a single hard gelatin or HPMC capsule without them chemically reacting with one another.

Pharmacokinetics: Boosting the Bioavailability of Vitamin B6

While taste-masking is the primary driver for utilizing Vitamin B6 pellet coating technology, we cannot ignore the pharmacokinetic benefits.

The bioavailability of Vitamin B6 in its raw, uncoated form is generally good in healthy individuals. However, absorption occurs primarily in the jejunum. If a standard tablet dissolves too early in the harsh, highly acidic environment of the stomach (pH 1.5 – 3.5), a portion of the active ingredient can be degraded before it ever reaches the absorption site.

By applying an enteric or targeted-release Vitamin B6 pellet coating technology, we can ensure the payload survives the gastric phase. The coating is engineered to remain intact in stomach acid but dissolve rapidly in the slightly alkaline environment of the small intestine.

When you upgrade this to a liposomal pellet, the impact on the bioavailability of Vitamin B6 is profound. Once the outer protective coating dissolves in the intestine, the liposomal vesicles are released.

These phospholipid spheres protect the Pyridoxine from enzymatic degradation and facilitate direct cellular uptake.

WBCIL’s Commitment to Quality

Developing a robust Vitamin B6 pellet coating technology requires millions of dollars in equipment, stringent environmental controls, and an exceptionally skilled workforce. For most supplement brands and mid-tier pharma companies, building this infrastructure from scratch is economically unviable.

This is where strategic partnerships come into play.

If you are looking to elevate your product line, you need to buy pharmaceutical grade Vitamin B6 pellets from a manufacturer that understands both the chemistry of the API and the physics of the coating process.

Our liposomal Pellets are the pinnacle of this science. We don’t just supply raw materials; we supply engineered solutions. Our pellets are manufactured under strict WHO-GMP conditions that ensures absolute uniformity in particle size, coating thickness, and dissolution profiles.

When you integrate our Vitamin B6 pellet coating technology into your formulations, you are instantly eliminating patient complaints about bad taste, extending your product’s shelf life, and delivering a superior clinical outcome.

Looking Ahead: The Future of Taste-Masked Nutraceuticals

The international market has already shifted to liposomal technology. Consumers are no longer willing to tolerate “medicinal” tasting supplements, nor are they willing to consume products loaded with artificial sweeteners and thickeners. The demand for clean-label, highly bioavailable, and perfectly taste-masked products is driving the future of the industry. That’s why we have already launched our nutraceutical brand ‘cellular prime’.

Vitamin B6 pellet coating technology is just the beginning. The principles of utilizing advanced fluid bed processing and liposomal encapsulation can be applied to a vast array of bitter APIs, from botanical extracts to essential minerals.

By mastering the physical barrier—by truly understanding how to isolate the molecule from the tongue while delivering it efficiently to the blood—we are opening the door to new, innovative dosage forms. Think of flavorless vitamin powders that can be mixed into water, or chewable multivitamins that actually taste like candy without the sugar crash.

At WBCIL, we are proud to be at the forefront of this revolution. We have proven that with the right Vitamin B6 pellet coating technology, you don’t have to compromise between taste and efficacy. You can, in fact, have both.

At WBCIL, our fluid bed coating processes are strictly controlled using Quality by Design (QbD) principles. We engineer the specific weight-gain of the polymer or lipid coating to match your exact release profile requirements (immediate, sustained, or enteric), ensuring full compliance with USP/EP dissolution standards while maintaining 100% taste masking.

Absolutely. Our Vitamin B6 pellet coating technology creates a physical barrier, meaning the bitterness is neutralized mechanically rather than chemically masked by sweeteners. This allows you to formulate diabetic-friendly, sugar-free chewables or ODTs that feature a perfectly clean label and a neutral flavor profile.

Polymer coatings primarily serve to protect the API from the environment (stomach acid, oxidation) and mask taste. Liposomal encapsulation goes a step further by wrapping the API in phospholipids to actively enhance cellular absorption. WBCIL offers the best of both worlds: dry, polymer-coated liposomal pellets that provide ultimate stability and maximum bioavailability.

Fluid bed coating is highly capital-intensive and requires specialized technical expertise to prevent agglomeration and uneven coating. By partnering with WBCIL, you bypass the massive capital expenditure and scale-up risks. You receive ready-to-fill, WHO-GMP certified pellets that guarantee consistent batch-to-batch quality and immediate market readiness.

Liquid liposomes are prone to oxidation, leakage, and require a cold chain. The stability of liposomal pellets in capsule dosage forms is vastly superior because WBCIL converts the liposomes into a dry, solid state. This locks the vesicles in place, preventing aqueous degradation, extending shelf life to 24+ months at room temperature, and allowing for easy high-speed capsule filling.