Nano-Nutrition 2026: Why Liposomal Delivery is Finally Replacing Traditional Tablets

As scientists and formulators, we face the complex reality of bioavailability. It is a bottleneck for the modern pharmaceutical and nutraceutical industries. We can engineer the most potent antioxidant or the purest mineral salt, but if the human body can’t absorb it, it’s biologically useless.

The pharma and nutra industry has relied on the “sledgehammer” approach of traditional tablets—packing high doses into compressed pills, hoping enough survives the harsh journey through the gut to make a difference. But as we settle into 2026, the data is forcing us to confront an uncomfortable truth: nearly 80% of standard oral supplements are never absorbed. They are degraded by stomach acid, broken down by enzymes, or filtered out by the liver before they ever reach a cell. How to enhance the bioavailability? The inefficiency is no longer acceptable.

We are witnessing a paradigm shift toward the future of liposomal delivery systems. This isn’t just a marketing trend; it’s a technological evolution driven by pharmacokinetics. We are moving from “macro” delivery to “nano” precision. This blog explores the mechanisms, data, and reasons why liposomal delivery is replacing traditional tablets in 2026, and how WBCIL Innovative Nutraceutical Solutions is engineering the particles that enable it.

Key Takeaways

- Bioavailability is King: The future of liposomal delivery systems is driven by the fact that they can increase nutrient absorption by up to 90%, rendering the “mega-dose” strategy of traditional tablets obsolete.

- Mimicking Biology: Next-generation nanonutrition technology uses phospholipid bilayers that mimic human cell membranes, allowing nutrients to fuse directly with cells and bypass digestive destruction.

- Precision Manufacturing: True efficacy depends on particle engineering. WBCIL Nanotechnology research centre ensures stability, size uniformity (100-300nm), and accurate encapsulation, distinguishing real liposomes from simple emulsions.

The Tablet Graveyard: Physiological Barriers to Absorption

To understand why tablets are becoming obsolete, we have to look at human physiology. The GI tract is designed to be a barrier, not just a gateway.

- The Acid Trap: The stomach’s pH drops to between 1.5 and 3.5. This acidic environment hydrolyses sensitive compounds such as Vitamin C, Glutathione, and peptides immediately.

- Enzymatic Breakdown: Whatever survives the acid faces a gauntlet of digestive enzymes in the small intestine.

The “First-Pass” Filter: Even if a nutrient is absorbed, it enters the hepatic portal vein and goes straight to the liver, which aggressively metabolises foreign substances (first-pass metabolism).

This explains the difference between liposomal delivery and standard oral tablets. A tablet exposes the naked nutrient to all these threats. A liposome acts as a shield.Biomimicry: How Nano-Encapsulation Works

So, how does nano-encapsulation improve pharmaceutical efficacy? The answer lies in biomimicry—imitating biology to bypass biological defences.

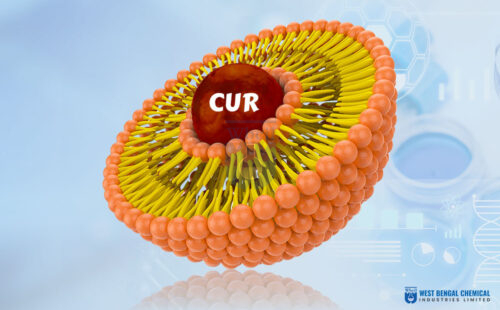

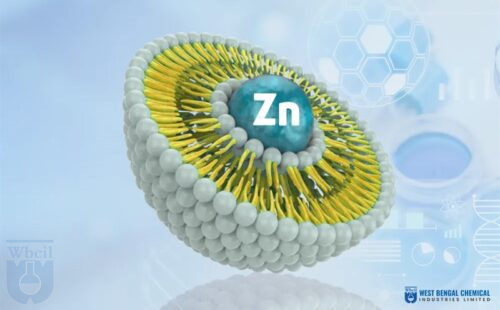

A liposome is a microscopic sphere (vesicle). Its outer shell is made of a phospholipid bilayer—the exact same double-layer of fat molecules that makes up the membranes of every cell in your body.

By trapping the active ingredient (API) inside this phospholipid sphere, we achieve three critical things: - Protection: The lipid shell resists gastric acid, keeping the payload intact.

- Camouflage: The body recognises the phospholipid surface as “self,” allowing it to slip past immune defences.

- Fusion: This is the key. The liposome can fuse directly with the intestinal cell membrane, delivering its nutrient payload into circulation.

This mechanism is the foundation of next-generation nano-nutrition technology. It converts a passive supplement into a targeted delivery vehicle.The Data: Why 2026 is the Tipping Point

In science, data drives adoption. The reason liposomal delivery is replacing traditional tablets in 2026 is simply that the pharmacokinetic numbers are undeniable.

- Vitamin C: Clinical data show that liposomal encapsulation increases bioavailability by approximately 80-90% compared to free ascorbic acid powder.

- Curcumin: Standard curcumin is notoriously difficult to absorb (less than 1%). Next-generation nano-nutrition technology utilising liposomes has been shown to boost this by up to 20-fold.

- Glutathione: Oral glutathione was once considered useless due to rapid breakdown. Liposomal delivery has made oral supplementation clinically viable, raising intracellular levels effectively for the first time.These stats highlight the benefits of liposomal delivery for nutrient absorption. In 2026, formulation efficiency is the new benchmark for quality.

Current Trends: Nano-Bioavailability in 2026

The future of liposomal delivery systems is being shaped by specific market forces this year:

1. The “Clean Label” Evolution

Consumers and clinicians alike are demanding purity. They don’t want synthetic binders, glues, or shellacs found in tablets. Liposomes, typically derived from non-GMO sunflower or soy lecithin, offer a cleaner alternative. This aligns with nano-bioavailability trends 2026, where the delivery system itself (the phospholipid) is a beneficial nutrient (phosphatidylcholine) rather than an inert filler.

2. Solving Solubility Issues

Many of the most promising therapeutic compounds (like CoQ10, Curcumin, and Cannabinoids) are hydrophobic—they hate water. The body is mostly water. This solubility mismatch is a major hurdle. Advanced pharmaceutical nutrient delivery using liposomes solves this by trapping these fat-soluble nutrients within the lipid bilayer, making them dispersible in water-based systems (such as blood).

3. Precision Dosing

Because absorption is so much higher, we can use lower doses of the Active Pharmaceutical Ingredient (API) to achieve the same, or better, clinical effect. This is how nano-nutrition technology is changing the pharmaceutical landscape—it’s making treatments more efficient and cost-effective.

The WBCIL Approach: Engineering, Not Just Mixing

It is important to note that not all “liposomes” are created equal. Mixing oil, water, and vitamin powder in a blender creates an emulsion, not a liposome.

As your Liposomal API manufacturing partner, West Bengal Chemical Industries Limited (WBCIL) approaches this as a nanoscience discipline. At the WBCIL Nanotechnology research centre, we utilise rigorous characterisation methods:

- Dynamic Light Scattering (DLS): To confirm the particle size is in the “Goldilocks zone” (100-300nm). Too big, and they aren’t absorbed; too small, and they are unstable.

- Zeta Potential Analysis: To ensure the particles have the right electrical charge to stay suspended and not clump together.

- Encapsulation Efficiency: To verify that the nutrient is actually inside the sphere.

WBCIL Patented Delivery Systems

Innovation requires protection. WBCIL has developed patented delivery systems to tackle the toughest molecules, such as iron.

Our Liposomal Ferric Pyrophosphate is a prime example. Iron usually tastes metallic and upsets the stomach. By locking it inside our proprietary phospholipid shell, we mask its taste completely, prevent gastric irritation, and maximise absorption via the lymphatic route.Conclusion: The End of the “Mega-Dose” Era

For years, the industry’s answer to poor absorption was just “add more.” If 200mg doesn’t work, give them 1000mg.

The future of liposomal delivery systems allows us to be smarter. We can stop flooding the body with excessive raw materials and start delivering precise, protected, and effective dosages.

For pharmaceutical and nutraceutical companies, the shift is clear. The era of the compressed tablet is fading. The era of the engineered particle is here. Partnering with a specialised Liposomal API manufacturing partner like WBCIL isn’t just an upgrade; it’s a necessary evolution to stay relevant in the scientific landscape of 2026.

We don’t guess; we measure. At the WBCIL Nanotechnology research center, we use Transmission Electron Microscopy (TEM) to visually confirm the spherical bilayer structure and Dynamic Light Scattering (DLS) to measure precise particle size distribution. We provide Certificates of Analysis that include Entrapment Efficiency data, proving that the API is physically secured within the next-generation nano-nutrition technology rather than mixed into oil.

Yes, this is a core strength of WBCIL’s Patented delivery systems. The phospholipid bilayer of a liposome has a “fat-loving” region that naturally traps hydrophobic molecules like Curcumin or CoQ10. This allows us to solubilise these difficult ingredients into water-dispersible formats, drastically improving their bioavailability—a key advantage in advanced pharmaceutical nutrient delivery.

Stability is the biggest challenge in liposomal manufacturing. WBCIL has developed proprietary stabilisation techniques (often involving lyophilisation or specific zeta-potential tuning) that enable many of our liposomal powders to remain stable at room temperature. We provide accelerated stability data (40°C/75% RH) to support shelf-life claims, ensuring the future of liposomal delivery systems is commercially viable.

Traditional iron tastes metallic and creates free radicals that irritate the stomach lining. Our WBCIL Patented delivery systems for Ferric Pyrophosphate encapsulate the iron core completely within a lipid barrier. This prevents the iron from touching taste buds or the stomach mucosa, effectively eliminating the metallic taste and GI side effects while utilising M-cell pathways for superior absorption.

Absolutely. We are an industrial Liposomal API manufacturing partner, not just a research lab. We have scaled our homogenization and encapsulation processes to produce metric tons of liposomal ingredients without compromising particle integrity. We offer the consistency and volume required for global supply chains in the nano-bioavailability trends 2026 market.