The 15% Yield Revolution- Hidden Profits in Paneer Manufacturing

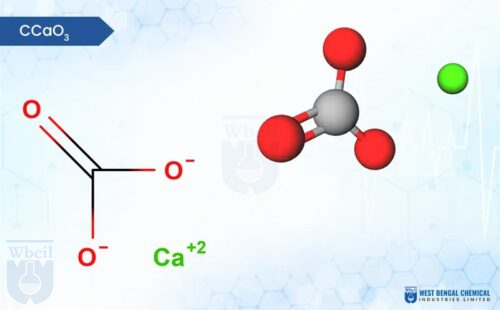

Are You Leaving Money on the Factory Floor?

If you run a dairy processing unit, you know the drill. You negotiate milk prices down to the paisa, optimize your heating cycles, and watch your coagulation process like a hawk. Yet, despite your best efforts, margins in the paneer industry remain notoriously tight.

We often accept a certain “standard” yield as an immutable law of nature. We assume that 100 liters of milk will give us roughly 14 to 15 kilograms of paneer, and that’s that. But what if that wasn’t the limit? What if the chemistry of your coagulation could squeeze out an extra 10-15% of product from the exact same volume of milk?

At West Bengal Chemical Industries Limited (WBCIL), we have moved past the “lemon and vinegar” era. We are looking at the molecular engineering of dairy, and the results are changing the game.

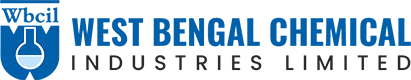

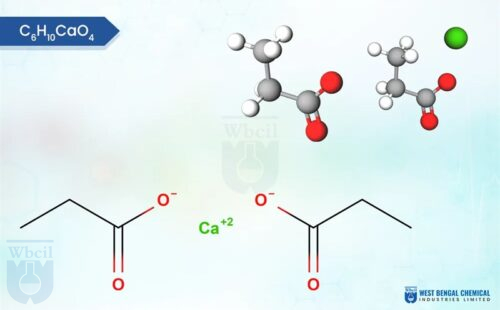

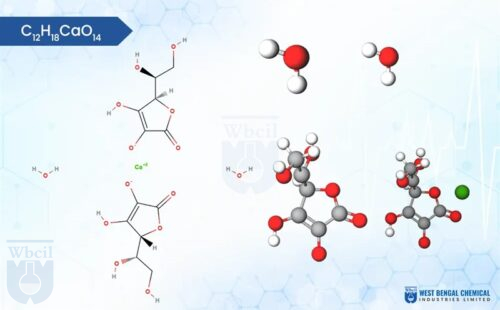

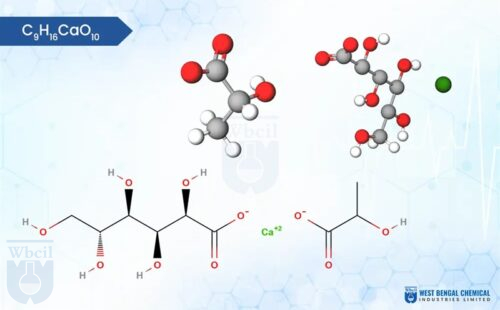

The secret isn’t magic; it’s calcium acetate in paneer—specifically when blended intelligently with Glucono Delta Lactone (GDL) and Calcium Chloride (CaCl2). Let’s dive deep into why this specific chemical architecture is the breakthrough your production line has been waiting for.

Key Takeaways:

- Switching from “violent” traditional coagulation methods to WBCIL’s controlled Calcium Acetate blend can boost paneer yield by a conservative 10-15%.

- The blend creates a stronger protein “calcium bridge” that traps more moisture and fat, simultaneously increasing profits and creating a premium, sliceable texture.

- WBCIL provides FSSAI-approved, high-purity additives manufactured under WHO GMP guidelines, ensuring regulatory compliance and consistent batch-to-batch performance.

The “Violent” Coagulation Problem

To understand the solution, we first have to look at why traditional methods fail to maximize yield.

For decades, paneer makers have relied on Citric Acid or Acetic Acid (vinegar) to coagulate milk. It works, sure. But from a chemical standpoint, it’s a sledgehammer approach. These acids drop the pH of the milk rapidly and unevenly. This “shock” causes the casein micelles (the protein structures) to collapse quickly.

The result of rapid acidification?

- Shattered Curd: The protein network forms too fast to trap moisture effectively.

- High Whey Loss: Valuable solids and fats are washed away into the whey water.

- Inconsistent Texture: You often end up with a crumbly product that consumers hate.

You aren’t just losing water; you are losing weight, volume, and ultimately, revenue.

Enter the “Smart Blend”: Calcium Acetate + GDL + CaCl2

This is where the science of WBCIL steps in. We aren’t just selling chemicals; we are selling a controlled reaction. By shifting to a blend involving a calcium acetate food additive, you move from a “shock” process to a “controlled build” process.

1. The Calcium Bridge (The Yield Booster)

This is the most critical concept. Milk proteins (caseins) are negatively charged and repel each other. To get them to stick together and form curd, you need to neutralize that charge.

Calcium is the perfect “bridge.” It creates cross-links between protein strands. When you introduce Calcium Acetate alongside Calcium Chloride, you are supercharging the milk with available calcium ions.

More Calcium = More Cross-linking.

More Cross-linking = A denser, stronger 3D protein network.

This stronger network acts like a finer net, trapping fat globules and moisture inside the paneer rather than letting them bleed out. That is where your extra 10-15% yield comes from. It’s solid mass that used to go down the drain.

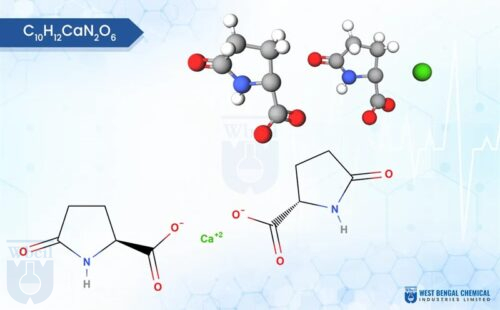

2. The Controlled Acidification (GDL)

Glucono Delta Lactone (GDL) is unique because it hydrolyzes slowly. Instead of the instant pH drop of citric acid, GDL lowers the pH gradually over time.

When combined with the buffering capacity of calcium acetate in paneer, this creates a “slow-motion” coagulation. This allows the protein strands to arrange themselves into a perfectly organized lattice structure. A better structure means the paneer holds its shape better and slices cleanly without crumbling.

The Economic Impact: Doing the Math

Let’s stop talking chemistry and start talking rupees. Imagine a medium-sized dairy plant processing 10,000 liters of milk per day.

Standard Process: 15% yield = 1,500 kg of Paneer.

WBCIL Blend Process: 16.5% yield (a conservative 10% boost) = 1,650 kg of Paneer.

That is an extra 150 kg of paneer every single day using the same amount of milk. Over a month, that is 4,500 kg of “free” product generated simply by optimizing your chemical inputs.

Key Insight: In the calcium acetate in cheese industry, milk is your highest cost. Any technology that maximizes milk utilization is not just an efficiency upgrade; it is a direct profit multiplier.

Beyond Yield: The “Premium” Texture

Yield gets the CFO excited, but texture is what keeps the customers coming back. The Indian consumer has become sophisticated. They don’t just want a block of white cheese; they want paneer that is soft yet firm, distinct, and sliceable.

Calcium acetate for paneer shelf life and texture plays a pivotal role here. It acts as a buffer, preventing the pH from dropping too low.

Too Low pH: The paneer becomes hard, dry, and acidic (sour).

Optimized pH: The paneer remains soft, retains moisture, and has that creamy, fresh milk taste.

With WBCIL’s food grade calcium acetate, you achieve a uniform pore structure. This means when a chef or a home cook slices your paneer, the knife glides through. It holds its shape in boiling gravy and doesn’t dissolve. That is the hallmark of premium export-quality paneer.

Regulatory Safety: The Clean Label Advantage

One of the biggest hurdles for Indian dairy exporters is meeting the stringent standards of the FDA, EU, and global food safety bodies.

At West Bengal Chemical Industries Limited, we specialize in high-purity mineral salts. Our calcium acetate powder for cheese industry is manufactured under strict WHO GMP (Good Manufacturing Practices) guidelines.

FSSAI Approved: Fully compliant with Indian food safety regulations.

No “Nasties”: This isn’t a synthetic calcium acetate preservative for dairy cocktail. It is a mineral-based processing aid that mimics natural milk salts.

Export Ready: High purity means low heavy metal content, ensuring your paneer passes the strictest quality checks for international export.

Why WBCIL?

You might ask, “Can’t I just buy generic chemicals?”

You could. But in food processing, purity is everything. Generic industrial chemicals often carry impurities—trace metals, varying concentrations, and inconsistent moisture content. In a biological medium like milk, even a tiny variance in your input chemicals can ruin a batch worth lakhs.

WBCIL offers:

- Consistency: Every batch of calcium acetate application in dairy acts exactly the same. You don’t have to recalibrate your machines every time you open a new bag.

- Scalability: Whether you are an artisanal producer or a massive industrial plant running 24/7, our supply chain is robust enough to keep you running.

- Technical Partnership: We don’t just drop off bags at your loading dock. We understand the chemistry of dairy. We help you understand how to integrate these salts into your specific thermal processing line.

Conclusion: The Next Step for Your Dairy

The dairy industry is getting crowded. To survive and thrive, you cannot rely on old methods that waste 10% of your raw material.

Switching to a Calcium Acetate + GDL + CaCl2 blend is one of the lowest-risk, highest-reward changes you can make in your production line. It bridges the gap between artisanal quality and industrial efficiency.

You get more paneer. You get better paneer. And you get a partner in WBCIL who ensures you never have to worry about the quality of your inputs.

Ready to stop pouring profits down the drain? Contact the WBCIL team today.

- http://ecoursesonline.iasri.res.in/mod/page/view.php?id=4060

- https://www.uoguelph.ca/foodscience/book-page/milk-coagulation

- https://www.sciencedirect.com/science/article/pii/S095869461630192X

- https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/calcium-chloride

- https://www.journalofdairyscience.org/article/S0022-0302(98)75669-8/pdf

- https://www.fssai.gov.in/upload/uploadfiles/files/Compendium_Food_Additives_Regulations_08_09_2020.pdf

- https://www.fao.org/food/food-safety-quality/scientific-advice/jecfa/jecfa-additives/detail/en/c/133/

- https://pubmed.ncbi.nlm.nih.gov/23572557/

- https://www.caltech.edu/news/milk-proteins-hook-form-network-cheese-1514

- https://www.who.int/medicines/areas/quality_safety/quality_assurance/gmp/en/

Traditional coagulants use a “sledgehammer approach,” causing a rapid and uneven drop in pH. This “shock” leads to a shattered curd structure that fails to trap moisture effectively, causing valuable solids and fats to wash away with the whey water.

Calcium Acetate provides calcium ions that act as a “bridge,” creating cross-links between protein strands. This forms a denser, stronger 3D protein network that traps more fat globules and moisture inside the solid mass instead of letting them escape, directly increasing yield.