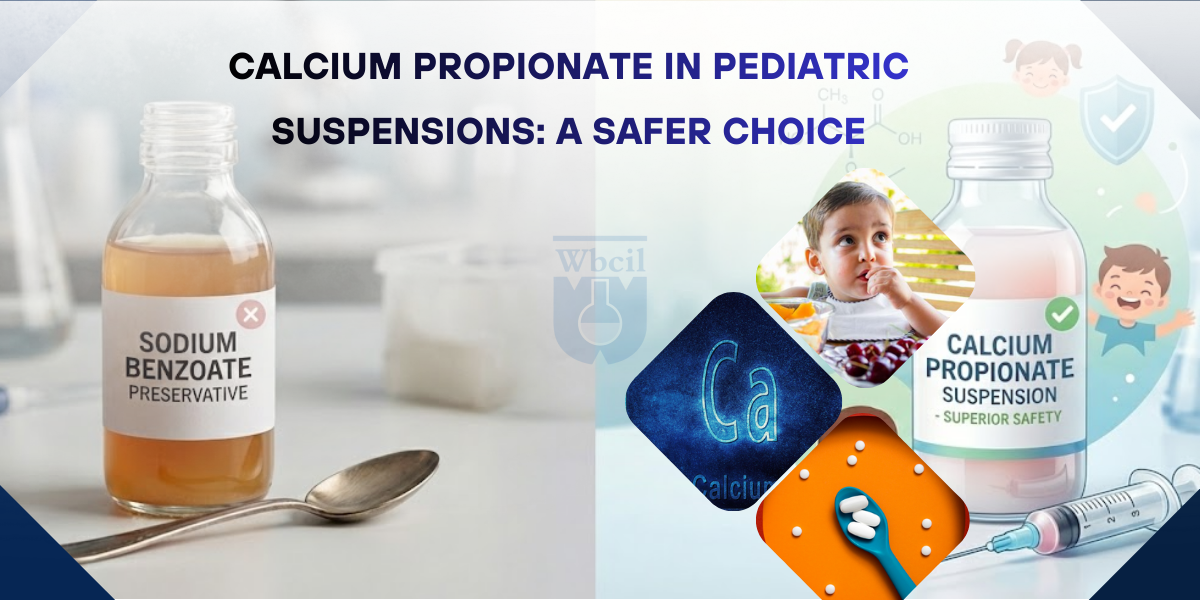

Beyond Benzoates: Why Calcium Propionate in Paediatric Suspensions Is the Superior Preservative

Preservatives play a significant role in paediatric medicines, and formulators prioritise safety, stability, and tolerability at all times. Moreover, every excipient choice carries specific responsibilities, mainly when products are intended for infants and children.

Growing scrutiny around benzoates has encouraged manufacturers to reassess preservative strategies in oral liquid formulations. Calcium propionate has emerged as a technically robust option, offering antimicrobial protection alongside favourable safety and formulation characteristics.

In this blog, we will explore why calcium propionate in paediatric suspensions is more effective than benzoates.

Key Takeaways

- Calcium propionate has a wider pH stability and mould control than benzoates in paediatric suspensions.

- Regulatory safety data is critical to support regulatory oversight of paediatric products undergoing formulation-specific evaluation.

- Formulation efficacy of preservatives mandates pH optimisation, excipient compatibility, and antimicrobial activities of paediatric suspensions.

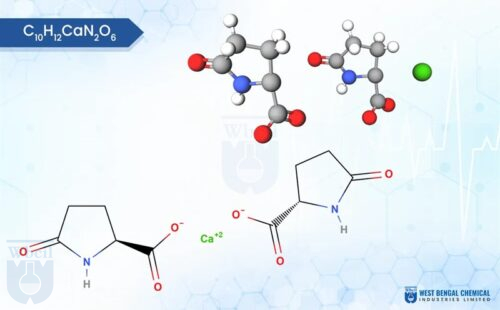

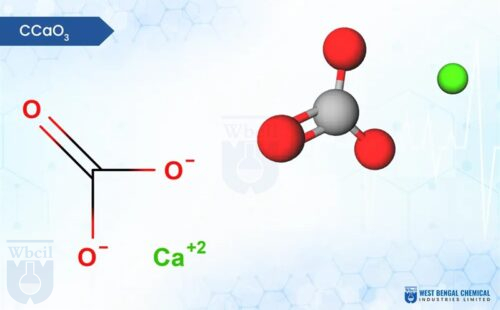

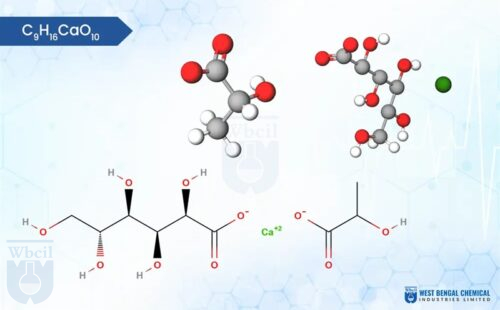

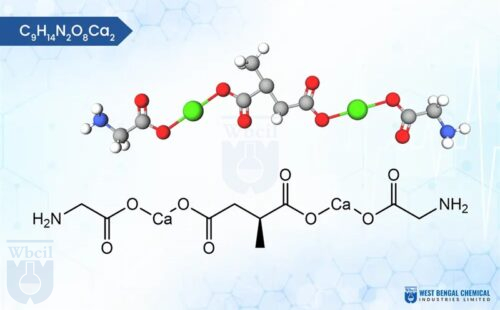

What Is Calcium Propionate and How Does It Work as a Preservative

Calcium propionate, also known as the calcium salt of propionic acid, is a critical antimicrobial agent in food and pharmaceutical products because it effectively inhibits microbial growth. It dissolves in aqueous bases and discharges propionic acid, disrupting microbial metabolism, which is critical to extend shelf life.

Moreover, these properties serve as the basis for calcium propionate in paediatric suspensions and formulations.

Its antimicrobial action is strongest at acidic pH (below 5.5), where the undissociated acid penetrates microbial cells more readily [1]. Inside microbes, propionic acid interferes with enzyme activity and nutrient uptake, preventing replication and growth. Compared with some preservatives, such as sodium benzoate, calcium propionate shows stronger inhibition of moulds without affecting the desired yeast activity.

Calcium Propionate in Paediatric Suspensions: Safety and Regulatory Considerations

Regulatory reviews demonstrate that calcium propionate has a high no-observed-adverse-effect level (NOAEL) of up to 400 mg/kg/day in developmental toxicity studies [2]. Moreover, the evidence also highlights consideration of calcium propionate in paediatric suspensions under strict formulations.

- Recognised as safe by authorities: Calcium salt is safe when preservatives are concerned, with formal safety evaluations supporting its general use.

GRAS designation: In the United States, the FDA classifies calcium propionate as “generally recognised as safe” (GRAS), reflecting its long history of accepted use. - Metabolism and non-toxic profile: Recent studies indicate that calcium propionate has a higher metabolism rate. Such low accumulation rates result in a low toxicity profile at approved use levels.

- Rare individual responses: Some small studies reported irritability and restlessness in children who consumed foods containing the preservative, but the evidence remains limited.

- Professional evaluation recommended: Despite strong safety data, formulators should assess preservative choices carefully for paediatric products and consult regulatory guidelines when designing suspensions.

With a better understanding of regulatory compliance, let’s explore the benefits to buy bulk calcium propionate APIs for paediatric formulations.

Benefits of Calcium Propionate over Sodium Benzoate in Pharmaceutical Use

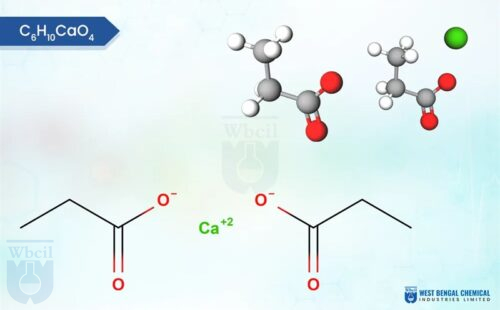

As a pharmaceutical-grade calcium propionate and antimicrobial preservative in paediatrics, it serves as one of the key alternatives to sodium benzoate in pharmaceuticals where formulation requirements differ.

Wider Active pH Range for Antimicrobial Protection

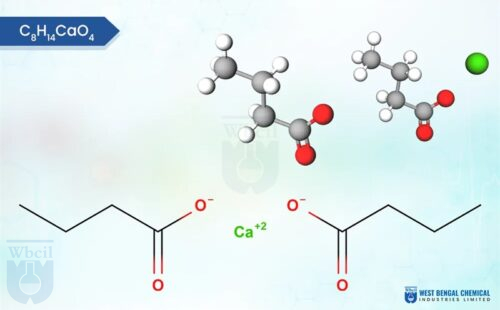

Calcium propionate remains effective in environments up to pH <5.5, whereas sodium benzoate’s optimal activity is limited to pH <4.0 for best antimicrobial effect. This makes calcium propionate more versatile in formulations that sit above low acidic conditions, such as paediatric suspensions and other liquid medicines.

Targeted Antimicrobial Spectrum

Both compounds have the ability to inhibit microorganism proliferation, but calcium propionate excels in restricting mould growth across its active pH range, which is crucial in many aqueous pharmaceutical products. Sodium benzoate’s effectiveness on the other hand reduces sharply outside its optimal pH range, limiting its utility in some formulations.

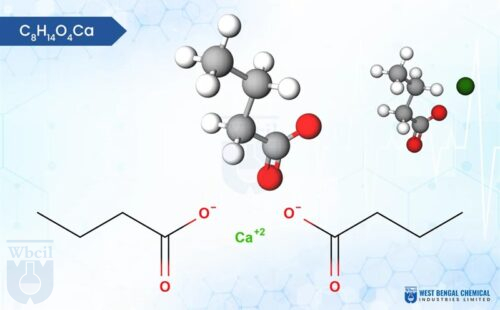

Functional and Nutritional Advantages

Calcium propionate delivers calcium ions, which adds nutritional value to some formulations compared with sodium benzoate. Moreover, calcium fortification allows for 21% increase in the calcium source in food products [3]. Although this is more relevant in food contexts, it may be beneficial in paediatric suspensions where calcium content can be advantageous.

Lower Acute Toxicity Profiles

Studies show that calcium propionate has low acute toxicity (LD₅₀ ~5100 mg/kg). Calcium propionate also exhibits inhibitory activity against yeast colonies; however, it is weak, and bacterial inhibition is higher. Sodium benzoate, in contrast, has an acceptable daily intake (ADI) set at 0–5 mg/kg body weight, limiting its use in higher-exposure scenarios.

Compatibility with Formulation Chemistry

Calcium API salts like calcium propionate interact in a versatile manner with excipients, which influences final product stability. For example, calcium propionate’s solubility characteristics support sustained activity without overly affecting viscosity or ph.

Also read: The Calcium Mystery- Why More Isn’t Always Better.

Now, let’s understand some of the best practices for using calcium propionate in paediatric suspensions.

Formulation Best Practices: Using Calcium Propionate in Liquid Suspensions

The development of liquid formulations, such as calcium propionate in paediatric suspensions, requires preservative selection based on excipient compatibility, pH, and other cofactors.

As a pharmaceutical-grade calcium propionate, it offers formulators a technically sound alternative to sodium benzoate in pharmaceuticals, particularly for paediatric use.

- Optimise formulation pH: The antimicrobial effectiveness of propionate salts is pH-dependent, and moving outside optimal ranges may require up to 11.9-fold higher concentrations to maintain control [4].

- Evaluate excipient interactions: Surfactants, suspending agents, and polymers bind effectively with preservatives, which reduces free aqueous concentration and antimicrobial activities.

- Confirm antimicrobial spectrum: Preservatives must have the ability to demonstrate anti-bacterial activities, along with targeting yeasts and moulds through compendia antimicrobial effectiveness testing across shelf life.

- Assess long-term stability: Preservative performance must remain effective throughout typical product lifetimes of 24–36 months, including in-use conditions after opening.

- Apply risk-based development: Selection of an antimicrobial preservative in paediatrics should follow a quality-by-design approach, ensuring compatibility with APIs and excipients.

WBCIL’s Calcium Propionate for Manufacturers

WBCIL’s pharmaceutical-grade calcium propionate offers manufacturers a potent preservative solution with consistent quality of up to three years in powder form, supporting advanced formulations. As part of WBCIL products, calcium propionate is valued for its ability to inhibit mould and bacterial growth, extending product integrity and supporting formulation stability.

Manufacturers seeking a technically sound, pharmaceutical-grade calcium propionate API can leverage this versatile compound in preservative strategies for various liquid and solid applications.

Final Thoughts

The right preservative choice requires an optimal balance between formulation practicality and antimicrobial efficacy. Recent data show that calcium propionate in paediatric suspensions has the capacity to meet such requirements with appropriate formulation discipline.

Formulators should evaluate preservative performance early through pH profiling, excipient interaction studies, and shelf-life testing. WBCIL provides appropriate documentation support and formulation insight, which can reduce development risk. The approach supports reliable product outcomes while quietly strengthening trust in the finished brand.

1. https://foodadditives.net/preservatives/calcium-propionate/

2. https://www.sciencedirect.com/topics/pharmacology-toxicology-and-pharmaceutical-science/calcium-propionate

3. https://justlonghealth.com/can-calcium-propionate-be-used-instead-of-sodium-benzoate/

4. https://www.americanpharmaceuticalreview.com/Featured-Articles/343543-Antimicrobial-Preservatives-Part-Two-Choosing-a-Preservative/

Calcium propionate can inhibit mould growth over a wider pH range. Such characteristics suffice for a better safety profiles making it optimal for liquid formulations.

Some significant benefits include stability and a long shelf life, as well as excipient compatibility and antibacterial properties. These benefits make calcium propionate effective for paediatric formulations.

Compared to antimicrobial effectiveness, preservative compatibility is one of the first parameters preservatives must meet for paediatric use. However, additional formulation parameters may vary across nations.

For industrial applications, sodium benzoate is a popular choice, and it works best at lower pH with an appropriate intake rate. These unique characteristics demand close monitoring for paediatric product formulations.

Calcium propionate’s pH limit is a little higher than that of sodium benzoate, with a pH limit of 5.5. Such fluctuations within acidity levels have a genuine effect on formulation flexibilities.