How WBCIL Ensures Quality in Ferric Derisomaltose Production

Think of Iron as a wild stallion that can be both strong and hard to predict when let loose in the body (uncontrolled iron in the body “gallops” freely, which can result in oxidative stress, gastrointestinal upset, and hypersensitivity). The traditional method of administering iron can cause that galloping, untamed stallion to create oxidative damage and gastrointestinal upset. Because ferric derisomaltose provides a method of “taming” that stallion by enclosing it in a stable carbohydrate backbone, it provides a controlled release (“precision delivery system”) method of administering iron [1]. This innovative Ferric derisomaltose complex API requires unwavering manufacturing standards to achieve an exceptional Ferric derisomaltose purity profile [2]. The foundation of each macro batch (therapeutic gold) uses Ferric derisomaltose Manufacturing Standards established by West Bengal Chemical Industries Limited (WBCIL) to ensure consistent and effective conversion of raw potential into a product.

Key Takeaways:

- Uncompromising Ferric derisomaltose manufacturing standards form the foundation of every batch at WBCIL — from rigorous raw material selection and patented complexation processes to precise control of pH, temperature, and reaction kinetics — ensuring a highly stable ferric derisomaltose complex API with no detectable labile iron and exceptional safety for high-dose intravenous administration.

- WBCIL achieves an outstanding Ferric derisomaltose purity profile (>96% purity, narrow molecular weight distribution, absence of free ferric ions) through multilayered quality assurance, including orthogonal analytical techniques (SEC, dynamic light scattering).

- HPLC/spectroscopy/endotoxin checks, and comprehensive finished-product testing (ICP-MS for heavy metals, Karl Fischer for moisture, ICH stability studies), all enforced across WHO-GMP, cGMP, ISO, and FDA-registered facilities.

By maintaining superior Ferric derisomaltose manufacturing standards, WBCIL delivers a product with a linear oligosaccharide structure, low immunogenicity, and a favorable hypophosphatemia profile compared to alternatives like ferric carboxymaltose, enabling reliable, single-dose iron repletion up to 1,000–1,500 mg, supporting global bulk supply, and ultimately helping patients overcome iron deficiency anemia with confidence in purity, potency, and controlled delivery.

The Foundation of Manufacturing Technology

Every batch begins with selecting appropriate raw materials, which are at the core of our manufacturing technology.

Rigorous Sourcing and Precursor Selection

At WBCIL, manufacturers source high-quality precursors through our rigorous process to ensure that the iron hydroxide and derisomaltose purchased do not contain contaminants that would negatively impact the final products produced from those raw materials [3]. Like a master chef inspecting every ingredient, WBCIL applies rigorous testing to guarantee the foundation meets global benchmarks. This vigilance maintains Ferric derisomaltose manufacturing standards from the start, minimising risks in the production of the Ferric derisomaltose complex API.

Forging a Molecular Fortress

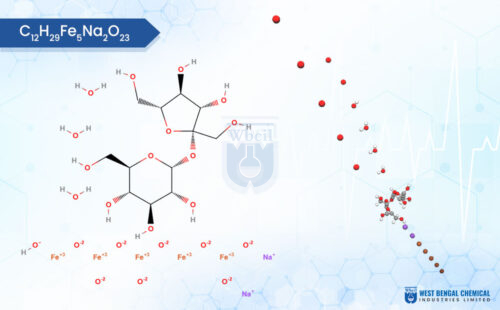

Synthesising ferric derisomaltose as an iron-delivery system is akin to forging a ‘molecular fortress’. A ferric hydroxide precipitate that subsequently forms a complex with derisomaltose (an isomaltooligosaccharide; linear, fully hydrogenated, average molecular weight of approximately 1000 daltons) consists of alternating layers of carbohydrate and ferric. These alternating layers of ferric & carbohydrate form a solid physical barrier which prevents the escape of any labile iron.

Patented Synthesis and Reaction Kinetics

WBCIL has patented methods for developing this stable structure, providing a very high degree of binding that allows the gradual release of iron to transferrin without creating toxic spikes [4]. Strict adherence to WBCIL’s manufacturing standards for Ferric Derisomaltose during synthesis enables control of pH, temperature, and reaction kinetics, resulting in a stable complex which can be safely administered to patients when infused at high doses [5].

Advanced Characterization and Particle Behavior

Ferric derisomaltose purity profile shines through advanced characterisation.

Orthogonal Testing Techniques

Using orthogonal techniques such as size-exclusion chromatography (SEC) and dynamic light scattering, WBCIL determines the molecular weight distribution [6].

Why is this so important when it comes to the measurement of ferric derisomaltose (API)?

Because if you maintain a small amount of variation in the weight distribution of these particles, you can achieve consistent behaviour of particles during administration and form a predictable pharmacokinetic profile.

Ensuring Pharmacokinetic Predictability

WBCIL is continuously evaluating the distribution of ferric derisomaltose minigrains to determine if any variance exists in relation to the way these minigrains are absorbed and their stability. To make stable delivery of iron, you cannot understate the importance of carbohydrates in providing a physiological cocoon to protect against quick dissociation and to enable a single dose of up to 1,000-1,500 mg to be given at once [7].

How does WBCIL maintain high purity in Ferric derisomaltose production?

Through multilayered quality assurance. HPLC, spectroscopy, and endotoxin assays are performed as part of in-process checks to detect anomalies before production completion. Comprehensive testing is performed for each finished API (active pharmaceutical ingredient) on multiple components: Testing includes iron content, carbohydrates (ratio), heavy metals, endotoxins and free ferric iron. The typical level of purity of a batch of WBCIL’s ferric derisomaltose is above 96% with no detectable amounts of readily available or labile iron [8].

It is well known for its exemplary quality and purity, and remains one of the safest iron supplements on the market [9]. Similar stringent techniques are used to test impurities in pharmaceutical-grade iron salts so that comparative results can be generated for each material: ICP-MS (Inductively Coupled Plasma-Mass Spectrometry) is performed to determine trace elements; Karl Fischer Non Homogenous moisture determination is being used in most cases [10]; and Controlled Stability Studies determining that the drug product has sufficient stability and Compatibility at the time of use will take 24 months to complete, based on ICH applicable criteria for stability testing [11].

WBCIL enforces these manufacturing standards for ferric derisomaltose across its WHO-GMP-certified, ISO-certified, and cGMP-compliant facilities in West Bengal and Gujarat [12].

What is the difference between Ferric derisomaltose and Iron Isomaltoside 1000?

Originally, Iron Isomaltoside 1000 referred to the same entity, now standardised as ferric derisomaltose [13]. Some of the more recent differentiators in generics are present; however, WBCIL’s generic product meets the originator’s specified requirements, including a linear oligosaccharide structure, low immunogenicity, and an improved hypophosphatemia profile compared to ferric carboxymaltose [8]. The evolution of these characteristics emphasises the importance of high manufacturing standards for Ferric derisomaltose, given the need for continuity in both nomenclature and quality for interchangeability [14].

Multilayered Quality Assurance and Global Compliance

By employing rigid WBCIL standards to enforce quality assurance for iron salts, in addition to laboratory testing using durable test methods, WBCIL has implemented continuous refinement-audit programs, automated production methods, and green initiatives such as solar power units that maintain high quality with its expanded capacity to triple current production of Ferric derisomaltose without compromising on quality standards and thus providing bulk quantity of Ferric derisomaltose to meet all global demand [15].

WBCIL Ferric Derisomaltose Purity is the answer to helping individuals eliminate their anaemia [16]. Every bottle represents uncompromising science – from the way it was constructed through to the individual involved in the science of purity [17]. The patient receives confidence and iron through a system of delivery that is reliable and efficient. Not only does WBCIL offer bulk ferric derisomaltose suppliers, but also manufactures of ferric derisomaltose complex API, with a higher level of production than any established standard has ever achieved [18]. The science behind purity goes beyond being a surface trait of the product; it is a powerful, understated force that will assist in creating a better quality of life for all [19].

1.Intravenous ferric derisomaltose for the treatment of iron deficiency anemia – A comprehensive review on rapid iron repletion, low hypersensitivity rates, and single-infusion convenience. https://pubmed.ncbi.nlm.nih.gov/33580972/

2.Comprehensive Characterization And Quality Control Of Ferric Derisomaltose Manufactured By WBCIL To Ensure Purity And Potency For High-Dose Intravenous Iron Therapy – WBCIL-specific journal article on characterization, purity, and quality control (from IOSR Journal of Dental and Medical Sciences). https://www.iosrjournals.org/iosr-jdms/papers/Vol25-issue1/Ser-1/F2501012835.pdf

3.Ferric Derisomaltose API Manufacturer | Iron Isomaltoside 1000 – Official WBCIL product page detailing specifications, molecular details, and quality features. https://www.wbcil.com/api-fine-chemicals-nutraceutical/iron/ferric-derisomaltose

4.An evaluation of ferric derisomaltose as a treatment for anemia – Expert review on pharmacokinetics, safety, and efficacy. https://pubmed.ncbi.nlm.nih.gov/33317356/

5.High-Dose Intravenous Iron with Either Ferric Carboxymaltose or Ferric Derisomaltose: A Benefit-Risk Assessment – Balanced assessment of high-dose administration benefits and risks. https://pubmed.ncbi.nlm.nih.gov/36068430/

6.Ferric Derisomaltose – PubChem (NCBI) – Chemical structure, properties, and basic manufacturing insights from the National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/Ferric-Derisomaltose

7.Liposomal iron in moderate chronic kidney disease – Review of liposomal ferric formulations for improved bioavailability in CKD. https://pubmed.ncbi.nlm.nih.gov/31892487/

8.Safety and efficacy of iron isomaltoside 1000/ferric derisomaltose versus iron sucrose in patients with chronic kidney disease: the FERWON-NEPHRO randomized, open-label, comparative trial – Key trial data on safety and efficacy in CKD patients. https://pubmed.ncbi.nlm.nih.gov/32049331/

9.A systematic literature review and meta-analysis of the incidence of serious or severe hypersensitivity reactions after administration of ferric derisomaltose or ferric carboxymaltose – Meta-analysis on hypersensitivity profiles. https://pubmed.ncbi.nlm.nih.gov/37010731/

10.Liposomal iron in moderate chronic kidney disease – Review of liposomal ferric formulations for improved bioavailability in CKD. https://pubmed.ncbi.nlm.nih.gov/31892487/

11.Efficacy and Safety of Oral Supplementation with Liposomal Iron in Non-Dialysis Chronic Kidney Disease Patients with Iron Deficiency – Recent pilot on liposomal iron efficacy and safety. https://pubmed.ncbi.nlm.nih.gov/38732502/

12.Effects of Iron Isomaltoside vs Ferric Carboxymaltose on Hypophosphatemia in Iron-Deficiency Anemia: Two Randomized Clinical Trials – Compares hypophosphatemia incidence, highlighting advantages of ferric derisomaltose. https://pubmed.ncbi.nlm.nih.gov/32016310/

13.Intravenous ferric derisomaltose in patients with heart failure and iron deficiency in the UK (IRONMAN) – Landmark trial on cardiovascular outcomes and iron repletion. https://pubmed.ncbi.nlm.nih.gov/36347265/

14.Safety and Efficacy of Intravenous Ferric Derisomaltose Compared to Iron Sucrose for Iron Deficiency Anemia in Patients with Chronic Kidney Disease With and Without Heart Failure – Focuses on tolerability and faster hematological response. https://pubmed.ncbi.nlm.nih.gov/34162484/

15.Intravenous ferric derisomaltose versus saccharated ferric oxide for iron deficiency anemia associated with menorrhagia: a randomized, open-label, active-controlled, noninferiority study – Efficacy and safety in specific anemia etiologies. https://pubmed.ncbi.nlm.nih.gov/35790696/

16.Ferric derisomaltose for the treatment of iron deficiency anemia with postpartum hemorrhage: Results of a single-arm, open-label, phase 3 study in Japan – Postpartum application and safety profile. https://pubmed.ncbi.nlm.nih.gov/36653310/

17.Intravenous ferric derisomaltose for iron-deficiency anemia associated with gastrointestinal diseases: a single-arm, randomized, uncontrolled, open-label study – Efficacy in GI-related anemia. https://pubmed.ncbi.nlm.nih.gov/35867202/

18.Treatment of iron deficiency anemia with liposomal iron in inflammatory bowel disease: efficacy and impact on quality of life – Liposomal delivery in IBD anemia, enhancing credibility via alternative stable iron delivery mechanisms. https://pubmed.ncbi.nlm.nih.gov/32367457/

19.Nasal delivery of nanoliposome-encapsulated ferric ammonium citrate can increase the iron content of rat brain – Study on advanced liposomal/nanovesicular iron delivery for bioavailability insights. https://pubmed.ncbi.nlm.nih.gov/28578696/

Ferric derisomaltose uses a stable carbohydrate backbone to enclose the iron, creating a “molecular fortress” that provides a controlled release. This physical barrier prevents the escape of labile (unbound) iron, which is responsible for oxidative stress and toxic spikes in the bloodstream.

WBCIL has patented, solvent-free methods to develop a stable structure with high binding affinity, allowing for gradual iron release. Their standards include rigorous raw material vetting, precise control of pH and reaction kinetics, and multilayered quality checks across FDA-registered and WHO-GMP-certified facilities.

Maintaining a tight molecular weight distribution ensures that the iron particles behave consistently after administration. This creates a predictable pharmacokinetic profile, allowing clinicians to safely administer high single doses of up to 1,000–1,500 mg without rapid dissociation or adverse reactions.

WBCIL utilizes orthogonal techniques like size-exclusion chromatography (SEC) and dynamic light scattering to measure particle size. They also perform ICP-MS for trace element detection, HPLC for in-process checks, and endotoxin assays to ensure the final product meets a purity level of over 96%.

They are technically the same entity; Iron Isomaltoside 1000 was the original name, which has now been standardized as Ferric Derisomaltose. WBCIL’s generic version matches the originator’s requirements, offering a linear oligosaccharide structure and a lower risk of hypophosphatemia compared to other iron complexes like ferric carboxymaltose.