How WBCIL’s Patented Process Removes Chlorinated Impurities from Iron APIs

In pharmaceutical manufacturing, purity is a mandate, not just a goal. This is critical for intravenous iron therapies like Ferric Carboxymaltose. Patients with iron deficiency anemia need effective, safe treatments. Yet, making these complex iron carbohydrates involves chemical challenges. The most persistent issue is the formation of chlorinated impurities in APIs.

West Bengal Chemical Industries Limited (WBCIL) has solved this safety gap. As a leading api impurities manufacturer in india, we introduced a novel pathway through our Indian Patent 370845. This WBCIL-exclusive process for removing impurities eliminates toxic oxidizing agents like sodium hypochlorite. Instead, we use a safer reaction involving citric acid.

Explore WBCIL’s Ferric Carboxymaltose API specifications and applications here.

Key Takeaways:

- Traditional iron synthesis often uses bleach, risking the formation of hazardous genotoxic impurities in API structures.

- WBCIL’s patented method uses citric acid as a dual oxidizing and cross-linking agent to ensure safe iron particle formation.

- This innovation removes the need for expensive membrane filtration, setting a new standard for advanced purification of iron salts at WBCIL.

The Chemistry of the Old Problem

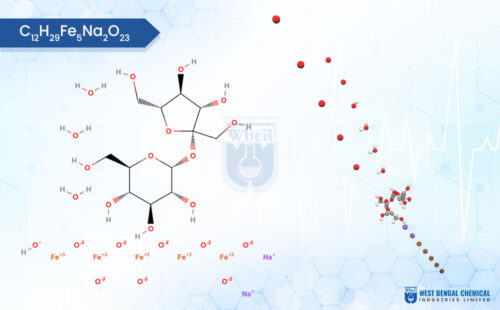

To understand the WBCIL innovation, we must look at impurity profiling of iron APIs in older methods. Traditional synthesis oxidizes maltodextrins to create a stable shell around an iron core. Historically, this used aqueous sodium hypochlorite (bleach) in an alkaline medium.

The Chlorine Conundrum

Using bleach introduces significant risks. The reaction generates large amounts of inorganic salts like sodium chloride. Worse, it causes side reactions with the carbohydrate shell. This leads to selective chlorination of iron values or the organic matrix.

These types of impurities in API are often flagged by ICH guidelines for safety. Traditional processes also require catalysts that add complexity. If not removed, they impact the drug’s safety. The industry needed advanced purification of iron salts that avoided introducing chlorine atoms—and WBCIL delivered.

WBCIL’s Solution: The Citric Acid Breakthrough

WBCIL’s patent re-imagines this oxidation step. We replaced sodium hypochlorite with citric acid.

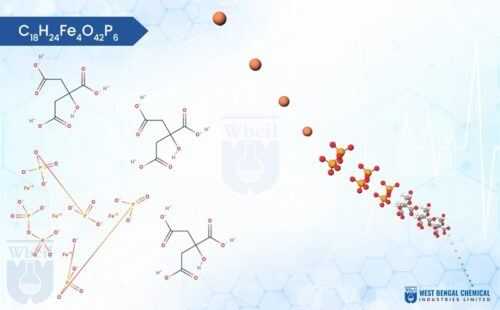

In the WBCIL process, citric acid serves two roles. It acts as a mild oxidizing agent and a cross-linking agent. This isn’t just a swap; it changes the reaction mechanics.

The Dual Role of Citric Acid

We use maltodextrin with dextrose equivalents (DE) between 10 and 20. In the presence of citric acid, these polymers form helical inclusion complexes. They wrap around the iron core under mild conditions.

This avoids the harsh environment of an electrochemical chlor-iron process or bleach oxidation. By removing hypochlorite, WBCIL removes the source of chlorine. Therefore, chlorinated impurities in APIs cannot form in our reaction vessels.

Step-by-Step: The WBCIL Purity Protocol

Our patent details a four-step process for total iron API impurities control .

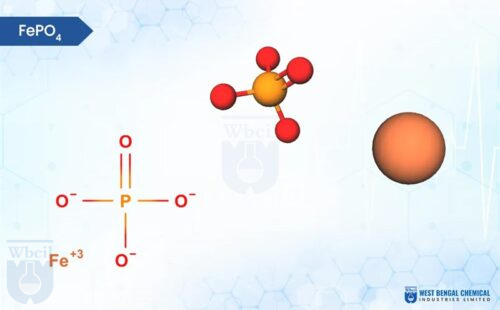

1. Preparing Ultra-Pure Ferric Hydroxide

At WBCIL, we begin by reacting ferric chloride with sodium carbonate. The critical factor is the wash. We rinse the precipitate until sodium chloride levels drop below 45 ppm. The chloride content within the precipitate must be less than 2.5% w/w. This ensures the iron particle formation starts with clean material.

2. The Chlorine-Free Complexation

Next, we add maltodextrin to the suspension. We do not add bleach. We add citric acid.

The WBCIL stoichiometry is precise. We use 0.4 to 1.2 equivalents of citric acid per aldehyde group. A preferred ratio is 0.72 equivalents. The mixture heats to 75-80°C for about 8 hours. Citric acid oxidizes the terminal groups and cross-links the polymer.

3. pH Adjustment and Stabilization

We cool the reaction mass to 35-45°C. We then adjust the pH to 7.0–8.0 using ammonia. This stabilizes the complex at a physiological pH.

4. Isolation Without Membranes

A major benefit of the WBCIL method is the simplified isolation. Older processes use costly membrane filtration to remove by-products. Because our reaction produces so few impurities, we skip that step. We filter the solution and spray-dry it. The result is a pure, water-soluble powder.

The Scientific Results: Data from the Patent

The patent data proves the efficacy of WBCIL’s process for removing impurities.

- Purity: The WBCIL Ferric Carboxymaltose achieves 96.88% purity.

- Yield: The process is efficient, delivering a 92% yield.

- Iron Content: It maintains an iron content of 34.55%.

- Molecular Weight: The mean weight is 82,000 Daltons.

Crucially, less than 10% of the complex is under 10,000 Da. This specific distribution prevents toxicity and ensures safe iron particle formation.

Why This Matters for Formulators?

For those seeking an api impurities manufacturer in india, partnering with WBCIL offers distinct advantages.

1. Regulatory Compliance

Regulators strictly monitor genotoxic impurities in API. By eliminating hypochlorite, WBCIL removes the risk of chlorinated organic by-products. This simplifies compliance with ICH guidelines.

2. Reduced Anaphylactic Risk

Safety is key for intravenous iron. Older dextran-based irons carried anaphylactic shock risks. The WBCIL process produces a non-dextran complex. This avoids those specific risks, allowing for higher safe dosages.

3. Cost-Effectiveness

The WBCIL process is cheaper. It cuts out expensive catalysts and phase transfer agents. It also avoids complex membrane filtration. We provide a cleaner product that is also affordable.

Conclusion

Indian Patent 370845 is a solution to a chemical hurdle. By replacing chlorination with citric acid, WBCIL has modernized Ferric Carboxymaltose manufacturing.

High purity does not require harsh chemicals. It requires smart chemistry. This patented process delivers an Iron API that is safe and stable. As a leading api impurities manufacturer in india, WBCIL is committed to purity.